- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

NHFLEX-A

Mining-grade rubber expansion joints are ruggedized solutions built to endure the punishing conditions of mineral extraction and processing. Featuring ultra-high molecular weight polyethylene (UHMWPE) abrasion liners and natural rubber carcasses, these joints excel in slurry pipelines, grinding circuits, and tailings disposal systems. Their thick-walled, multi-ply construction resists impact forces from oversized ore particles while accommodating misalignment in vibrating equipment like crushers and shaker screens. Compliant with MSHA and CORRA safety standards, they are the preferred choice for mines requiring explosion-proof and fire-retardant components.

1. Abrasion Resistance: 15mm-thick UHMWPE liners withstand 10+ years in 30% solids slurry flow.

2. High-Pressure Design: Reinforced with steel rupture discs for burst pressures exceeding 60 bar.

3. Impact Absorption: Energy-dissipating rubber compounds reduce peak G-forces by 40%.

4. Quick-Release Clamps: Facilitate liner replacement without disassembling pipeline sections.

5. Custom Geometry: Conical, elbow, or Y-shaped profiles engineered for complex routing.

· Copper Concentrate Pipelines: Handles abrasive chalcopyrite slurries at 6m/s flow rates.

· Coal Preparation Plants: Installed in dense medium cyclone feed and reject lines.

· Heap Leaching Systems: Resists sulfuric acid and cyanide solutions in gold extraction.

· Hydraulic Mining Monitors: Manages 500 psi water jets in alluvial deposit washing.

Q: What wear monitoring systems are available?

A: Embedded RFID tags or ultrasonic thickness sensors provide real-time liner wear data.

Q: Can joints handle sharp-edged materials?

A: Yes, our XR-3000 compound with Kevlar® reinforcement resists cutting from quartz and iron ore.

Q: Are explosion-proof models offered?

A: ATEX Category 3G joints with conductive liners prevent static discharge in coal dust environments.

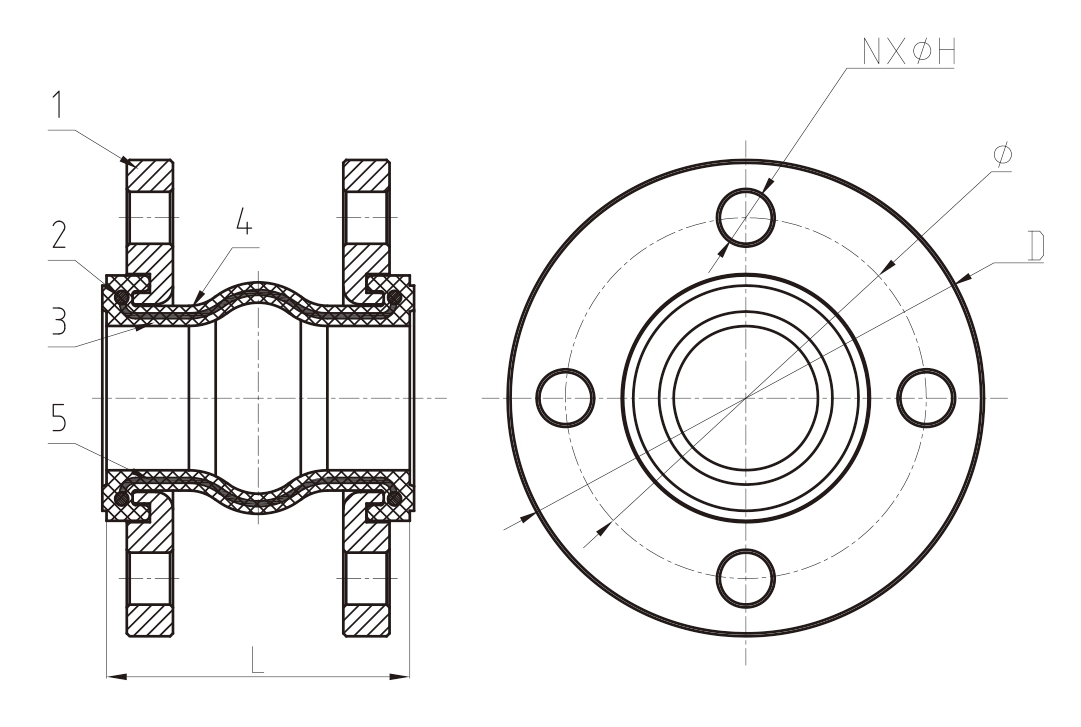

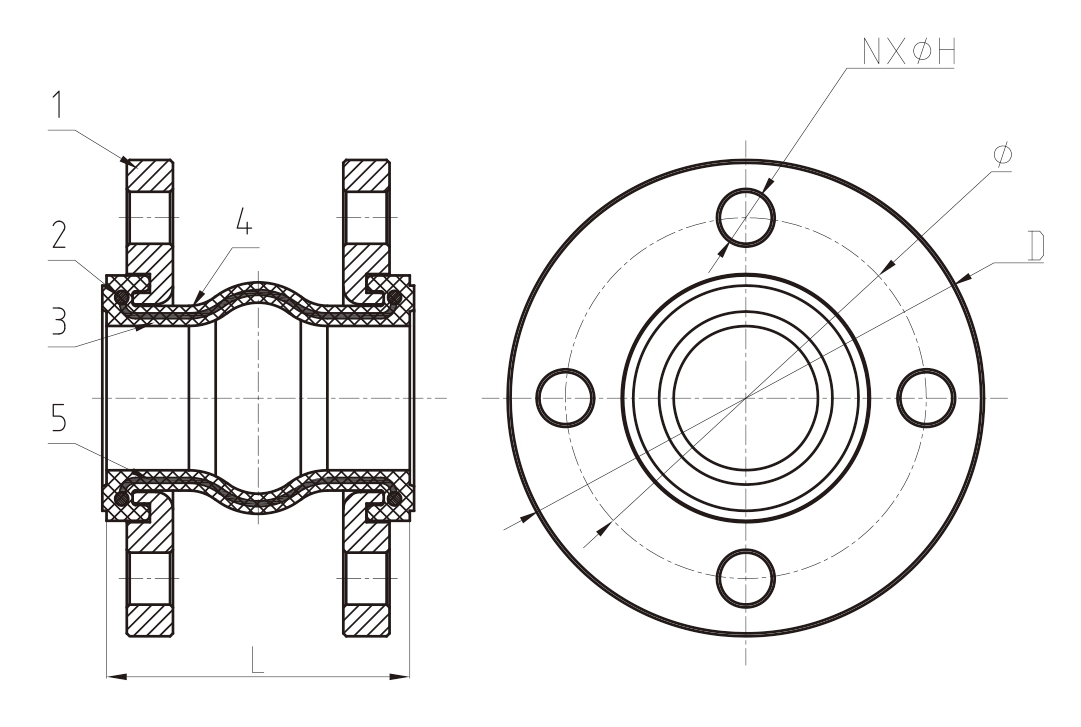

| MATERIAL SPECIFICATION | ||

| Part No. | Part | Standard Specification |

| 1 | Flange | Galvanized Carbon Steel |

| 2 | Reinforcing Ring | Carbon Steel |

| 3 | Rubber (lnner) | EPDM |

| 4 | Rubber (Outer) | EPDM |

| 5 | Reinforcing Fabric | Nylon Fabric |

Note: For special material request other than standard specification, please indicate clearly on the inquiry or order list.

Mining-grade rubber expansion joints are ruggedized solutions built to endure the punishing conditions of mineral extraction and processing. Featuring ultra-high molecular weight polyethylene (UHMWPE) abrasion liners and natural rubber carcasses, these joints excel in slurry pipelines, grinding circuits, and tailings disposal systems. Their thick-walled, multi-ply construction resists impact forces from oversized ore particles while accommodating misalignment in vibrating equipment like crushers and shaker screens. Compliant with MSHA and CORRA safety standards, they are the preferred choice for mines requiring explosion-proof and fire-retardant components.

1. Abrasion Resistance: 15mm-thick UHMWPE liners withstand 10+ years in 30% solids slurry flow.

2. High-Pressure Design: Reinforced with steel rupture discs for burst pressures exceeding 60 bar.

3. Impact Absorption: Energy-dissipating rubber compounds reduce peak G-forces by 40%.

4. Quick-Release Clamps: Facilitate liner replacement without disassembling pipeline sections.

5. Custom Geometry: Conical, elbow, or Y-shaped profiles engineered for complex routing.

· Copper Concentrate Pipelines: Handles abrasive chalcopyrite slurries at 6m/s flow rates.

· Coal Preparation Plants: Installed in dense medium cyclone feed and reject lines.

· Heap Leaching Systems: Resists sulfuric acid and cyanide solutions in gold extraction.

· Hydraulic Mining Monitors: Manages 500 psi water jets in alluvial deposit washing.

Q: What wear monitoring systems are available?

A: Embedded RFID tags or ultrasonic thickness sensors provide real-time liner wear data.

Q: Can joints handle sharp-edged materials?

A: Yes, our XR-3000 compound with Kevlar® reinforcement resists cutting from quartz and iron ore.

Q: Are explosion-proof models offered?

A: ATEX Category 3G joints with conductive liners prevent static discharge in coal dust environments.

| MATERIAL SPECIFICATION | ||

| Part No. | Part | Standard Specification |

| 1 | Flange | Galvanized Carbon Steel |

| 2 | Reinforcing Ring | Carbon Steel |

| 3 | Rubber (lnner) | EPDM |

| 4 | Rubber (Outer) | EPDM |

| 5 | Reinforcing Fabric | Nylon Fabric |

Note: For special material request other than standard specification, please indicate clearly on the inquiry or order list.

No.2 Taishan Road, Development Zone, Ningjin County, Shandong Province

Phone: +86-15806526381

+86-18561954252

Skype: rubberjoint1

Email: njninghaojixie@163.com